What Is GSM in Fabric and Why It Still Confuses So Many

If you’ve ever sourced fabric or tried to understand a garment’s quality, you’ve likely come across the term GSM. And yet, the question “what is GSM in fabric?” continues to puzzle buyers, designers, and even some merchandisers. At first glance, GSM looks like just another technical term. But once you dive into it, you’ll see that it’s one of the most important factors in apparel sourcing, pricing, and product performance. Without understanding GSM, choosing the right fabric is a bit like buying shoes without knowing your size.

Let’s unpack why GSM matters, how to interpret it, and how this one metric holds the key to a fabric’s weight, durability, and even its visual appeal.

GSM Meaning in Textile: The Full Form and Its Real Significance

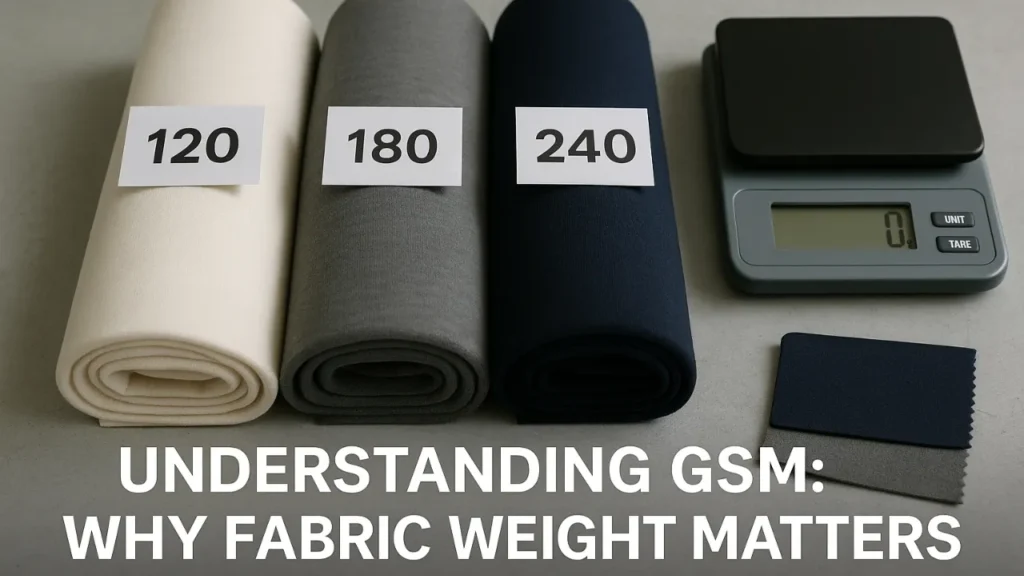

GSM stands for Grams per Square Meter. It measures how much a square meter of fabric weighs. The higher the GSM, the heavier (and often thicker) the fabric. For example, a 300 GSM fleece is warm, dense, and bulky, ideal for winterwear. A 120 GSM cotton? Light, breathable, and best for summer tees or linings.

People often confuse GSM with fiber quality. But GSM doesn’t define quality, it defines weight, which influences drape, structure, and use case. A 180 GSM cotton and a 180 GSM polyester will behave and feel completely different. That’s why understanding GSM is important but not the full story when selecting fabric.

In the textile world, GSM is the language of weight, and knowing how to interpret it is critical in design, pricing, and manufacturing.

The Language of Fabric: How GSM Connects Cloth, Weight, and Feel

Ever wondered why two T-shirts look identical but one feels more premium? It’s often a matter of GSM. When you know the gsm meaning fabric experts talk about, you can feel the difference before the label tells you.

Fabric with low GSM (say 100–130) feels light, flows more, and is usually chosen for warmer climates or base layers. On the other hand, high GSM (220–300+) fabrics feel heavier, warmer, and more structured.

This number tells you more than just weight, it speaks to comfort, durability, and purpose. A hoodie made with 300 GSM fleece will hold up in cold weather. A 150 GSM jersey tee is more suited for sunny days and active wear.

What GSM in Fabric Tells You Before You Even Touch It

Professionals often look at the GSM value before even touching the fabric sample. That’s because gsm in fabric means a lot more than weight, it tells a story.

Here’s what a simple GSM number can hint at:

- Will the fabric drape or hold structure?

- Is it breathable or dense?

- Can it withstand washing or will it wear thin?

- Is it suitable for winter jackets or lightweight scarves?

In sourcing meetings or production approvals, you’ll hear phrases like “this feels like a 180 GSM cotton” or “we need something around 240 GSM for this jacket.” It’s not guesswork, it’s industry language.

Having a fabric gsm chart on hand helps when comparing options or trying to match buyer expectations. Over time, GSM becomes less of a number and more of a fabric fingerprint, something that helps predict how the garment will behave once it’s worn, washed, or styled.

Understanding the Basics: GSM in Knit vs Woven vs Denim

Different types of fabric construction handle GSM differently. A 180 GSM single jersey knit feels nothing like a 180 GSM woven cotton shirting. Why? Because the density, fiber composition, and knitting vs weaving structure all impact how GSM translates into feel and behavior.

Here’s a quick breakdown:

Knit Fabrics: More stretch, softer feel, more volume per weight. Common for t-shirts, leggings, hoodies.

- 120–160 GSM: Lightweight summer tees

- 180–220 GSM: Midweight polos, basic sweatshirts

- 250–300+ GSM: Fleece, heavy hoodies

Woven Fabrics: Tighter, crisper, less stretch. Used for shirts, trousers, jackets.

- 120–180 GSM: Lightweight shirting or linings

- 200–300 GSM: Chinos, light jackets

- 350+ GSM: Canvas, twill

Denim Fabrics: Known for being heavy and durable.

- 280–400 GSM: Common denim jeans weight

- 400+ GSM: Workwear-grade denim

Denim, for example, can look soft but still weigh heavy due to its construction. That’s why denim fabric gsm and denim gsm are often listed on product specs to help buyers decide whether it’s light enough for fashion or thick enough for durability.

By understanding how GSM behaves across different fabric types, designers and merchandisers can pick the right textile not just by look, but by performance.

Best GSM for T-Shirts, Hoodies, and Activewear: A Designer’s Perspective

Let’s shift gears to application. Designers don’t choose GSM blindly, they choose based on function, style, and user behavior.

For T-Shirts:

A 160–180 GSM cotton jersey is the workhorse. It offers durability without stiffness and holds prints well. But for a premium retail line, going to 200 GSM gives a “thicker” and more luxurious feel.

Still, best gsm for t shirts depends on the context:

- Hot weather / gym: 130–150 GSM

- Streetwear: 180–200 GSM

- Premium minimalism: 200+ GSM

For Hoodies:

Go below 280 GSM and you’re risking a floppy silhouette. Stick to 300–330 GSM for structure and warmth. Anything more feels luxe, especially with brushed back fleece.

For Activewear:

Polyester blends at 180–220 GSM perform well. They’re breathable, fast-drying, and hold their shape through movement.

So yes, GSM is a design tool. The best gsm for hoodies isn’t just about warmth, it’s about how it will look, layer, and hold.

Why GSM Isn’t the Same as Thread Count and Why That Matters

There’s a misconception that GSM = thread count. It doesn’t. Thread count refers to how many yarns exist per inch in woven fabrics (usually bedsheets). GSM, on the other hand, is a weight measurement.

You could have two fabrics with the same thread count but wildly different GSM values depending on:

- Yarn thickness

- Fiber type

- Finishing processes

In short, gsm vs thread count is apples to oranges. For apparel, GSM is your go-to metric. Thread count is largely a home textiles concern.

This is why knowing the difference between gsm and thread count isn’t academic, it’s practical. One affects drape and feel. The other might not even apply to your fabric type.

Fabric Weight vs Thickness: How GSM Actually Affects the Garment Feel

Here’s where it gets tricky. Not all thick fabrics are heavy, and not all heavy fabrics are thick. That’s because fabric thickness gsm depends not just on grams per square meter, but on:

- Fiber density

- Weaving or knitting method

- Loftiness (fleece feels bulky but isn’t always heavy)

- Fiber composition (polyester vs cotton vs rayon)

Let’s say you’re holding two 240 GSM fabrics. One might feel dense and compact, the other fluffy and airy. Thickness can be visual. GSM, however, gives you the true density.

That’s why calculate fabric weight from gsm is often needed in costing or shipment documents. It’s not just for buyers, it’s for logistics too.

High GSM vs Low GSM: Durability, Drape, and Purpose

GSM impacts garment performance in three key areas:

- Durability: Higher GSM usually means longer-lasting fabric. A 300 GSM hoodie will survive rough handling better than a 160 GSM tee.

- Drape: Lower GSM fabrics tend to drape better and feel more relaxed. High GSM provides structure, which is great for boxy silhouettes or outerwear.

- Purpose Fit: Low GSM for summer, high GSM for winter. It’s a practical match.

And what about high gsm cotton fabric? It’s a designer’s favorite. The weight offers polish and luxury, while still breathing better than synthetics.

How to Calculate GSM: Formula, Tools, and Real-Life Use

If you’ve made it this far, you might be thinking: “Great, GSM is important. But how do I calculate it myself?”

Here’s the standard method professionals use across the textile industry:

GSM = (Weight of fabric sample in grams ÷ Area in square meters)

Sounds simple, but here’s how it works in practice:

- Cut a fabric sample that’s 10cm x 10cm (0.01 m²).

- Weigh it in grams using a precision scale.

- Multiply the result by 100 to scale up to 1 square meter.

For example, if your 10x10cm swatch weighs 2.4 grams:

2.4g × 100 = 240 GSM

This is the most common method used by sourcing teams during fabric development, especially when vendors don’t share verified specs.

Some also use fabric gsm calculation formula spreadsheets or apps that auto-convert based on sample dimensions. And for large-scale consistency, testing machines are brought in.

Lab Tests, GSM Testing Machines & Quality Control in Manufacturing

In bulk production, guessing isn’t an option. Brands rely on fabric gsm testing machines and lab testing methods to verify consistency between sample and bulk rolls.

These machines are simple but precise. They cut a sample with a GSM cutter (usually 100cm²), weigh it, and output the GSM instantly. This standardization ensures every fabric roll complies with the approved spec sheet.

Why is this critical?

Because even a 20 GSM variation between approved and bulk can cause issues in:

- Garment fit and drape

- Weight-based costing

- Shipping calculations

- Compliance with buyer specs

This is why many tech packs and purchase orders include GSM specs, and why fabric gsm test is an actual checkpoint in QA inspections.

Quality teams don’t just look at color or stitching. They measure the GSM to ensure what was promised is exactly what’s delivered.

Real-World Mistakes: When Brands Ignore GSM and Pay the Price

Let’s talk about consequences. Because ignoring GSM has cost brands more than just fabric returns.

We’ve seen brands approve a 180 GSM hoodie sample but receive 240 GSM bulk fabric. What happened? The heavier GSM made the hoodie stiffer, the stitching was tighter than expected, and it didn’t layer as easily. It completely missed the intended retail vibe.

In another case, a label went with 120 GSM fabric for premium tees thinking it would be breathable. The fabric was transparent and wrinkled easily. Customer returns skyrocketed.

The takeaway? GSM is not a “nice-to-have” spec, it’s a non-negotiable parameter in fabric sourcing.

What Designers, Buyers & Merchandisers Should Know About GSM

Understanding GSM allows each stakeholder to speak the same language:

- Designers can plan silhouettes and aesthetics better. Want drape? Go light. Want structure? Go heavy.

- Buyers can assess fabric expectations against price points. Heavier GSM typically means more raw material and higher costs.

- Merchandisers bridge both sides, ensuring that what’s sampled, sourced, and approved aligns with the final product.

Especially for startups and indie brands, learning about GSM early means fewer surprises. You’ll know what to expect from your production runs, and you’ll make smarter sourcing decisions, ones that save time, money, and reputation.

And when specs like best gsm for t shirts or high gsm cotton fabric come up in vendor discussions, you’ll no longer be guessing. You’ll be leading the conversation.

What Does RYZEAL Think About GSM in Fabric and Its Impact?

At RYZEAL SOURCING, we’ve seen firsthand how GSM in fabric affects not just the technical aspects of production, but also the emotional connection a buyer or customer feels with a product. The right GSM gives structure to a hoodie, breathability to a tee, and trust in a business relationship.

We treat GSM as a foundational spec, not an afterthought. From our initial sourcing to final quality inspection, we ensure all fabrics meet GSM expectations aligned with usage, climate, price point, and fashion direction.

Whether you’re working on lightweight fashion tees or launching a winterwear line, GSM helps us guide you in making choices that look right, feel right, and last.

Browse through more relatable blogs section at the footer to find more blogs.