Sourcing apparel overseas mistakes can lead to costly delays, quality issues, and communication breakdowns. Many brands struggle with unclear specifications, unreliable suppliers, and cultural misunderstandings that hurt their production timelines and budgets. By recognizing these common missteps early, businesses can take smarter steps to ensure successful sourcing abroad.

This guide provides expert insights into avoiding costly mistakes while sourcing apparel overseas, ensuring a smooth, ethical, and profitable supply chain.

Lack of Comprehensive Supplier Research

One of the most fundamental mistakes apparel brands make is failing to conduct thorough supplier research before committing to a partnership. Many companies rely solely on online directories or trade shows without verifying a factory’s credentials. This often results in subpar production quality, communication barriers, or hidden business risks.

How to Avoid This Mistake

- Utilize multiple sourcing platforms such as Alibaba, Global Sources, and Faire to cross-check supplier information.

- Conduct factory audits with third-party inspection agencies like SGS, Bureau Veritas, and TÜV Rheinland.

- Verify certifications such as ISO 9001 (quality management), WRAP (ethical labor standards), and OEKO-TEX (sustainable textile production).

- Request production samples and conduct thorough testing before placing large orders.

- Research past client reviews, business licenses, and supplier history to ensure reliability.

Ignoring Minimum Order Quantities (MOQs)

Many suppliers impose minimum order quantity (MOQ) requirements, which can be prohibitively high for small and mid-sized brands. Ignoring MOQs can lead to excess inventory, storage costs, or inability to meet order commitments.

How to Avoid This Mistake

- Discuss MOQ requirements upfront to ensure they align with your production needs.

- Seek out low-MOQ manufacturers that specialize in small-batch production.

- Partner with an apparel buying house that can aggregate orders across multiple clients to negotiate better terms.

- Explore flexible manufacturing solutions that allow scaling production volumes based on market demand.

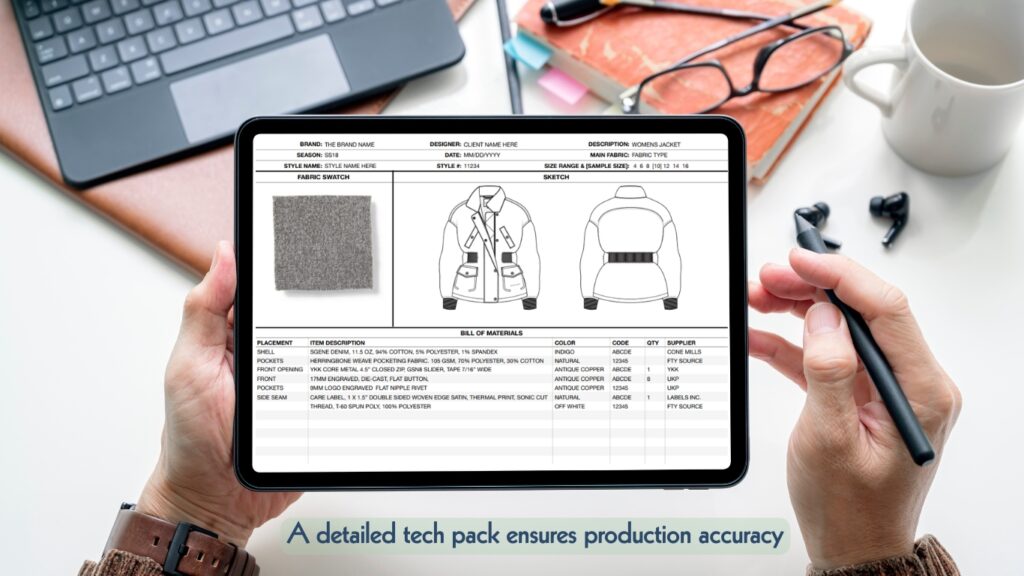

Failure to Provide a Detailed Tech Pack

A tech pack is an essential document that outlines the design, materials, construction details, and specifications for an apparel product. Without it, manufacturers may misinterpret designs, leading to quality issues and production inconsistencies.

How to Avoid This Mistake

- Work with experienced fashion designers or technical specialists to create a detailed tech pack.

- Include flat sketches, material descriptions, precise measurements, labeling details, color codes, and fabric swatches.

- Specify stitching, trims, and finishing details to maintain consistency across production batches.

- Use digital tools such as Techpacker or CLO 3D to streamline tech pack creation and communication with suppliers.

Underestimating Hidden Costs

Brands often focus on unit pricing while overlooking other expenses such as shipping fees, import duties, customs clearance, and quality control costs. These unexpected expenses can erode profit margins and disrupt cash flow.

How to Avoid This Mistake

- Request a detailed cost breakdown, including raw materials, labor, packaging, transportation, and logistics costs.

- Understand Incoterms (FOB, CIF, DDP) to clarify shipping responsibilities.

- Partner with a customs broker to estimate import duties and tax implications.

- Compare manufacturing costs across different sourcing regions to optimize pricing.

Choosing the Wrong Payment Terms

Many brands fall into the trap of paying suppliers in full upfront, leaving them vulnerable to fraud, delayed shipments, or substandard production. Payment mismanagement can lead to financial losses and disrupted supply chains.

How to Avoid This Mistake

- Negotiate split payments (deposit, mid-production, and final payment upon shipment) to mitigate financial risks.

- Use Escrow services or letters of credit (LCs) to protect transactions.

- Work with trade finance companies like Payoneer or Revolut Business for secure cross-border payments.

- Conduct small trial orders before committing to large transactions.

You don’t know what INCOTERMS are? Or want to jog your INCOTERMS Memory? Have a watch –

Skipping Quality Control Inspections

Failing to implement third-party quality inspections can result in receiving damaged, defective, or poorly made garments that do not meet brand standards.

How to Avoid This Mistake

- Hire independent quality control firms such as QIMA, Intertek, or Asia Inspection to perform pre-shipment inspections.

- Implement an Acceptance Quality Limit (AQL) system to define defect tolerance levels.

- Establish a standard operating procedure (SOP) for quality checks at various production stages.

- Use real-time monitoring tools to track production progress and address issues immediately.

RYZEAL’s Perspective: Mastering Apparel Sourcing Overseas – Challenges and Strategic Insights for 2025 and Beyond

Sourcing apparel overseas has long been a cost-effective strategy for fashion brands and retailers worldwide. However, as the global supply chain continues to face economic uncertainty, evolving trade regulations, and rising consumer expectations for ethical production, brands must rethink their sourcing strategies to remain competitive.

At RYZEAL Sourcing, we’ve worked with numerous global apparel brands to streamline their sourcing operations while mitigating risks. Our expertise allows us to navigate the complexities of overseas manufacturing, ensuring that brands can leverage high-quality, cost-effective solutions while maintaining brand integrity and compliance.

The New Age of Apparel Sourcing: Beyond Cost-Effectiveness

Traditionally, overseas apparel sourcing was driven by cost-saving incentives, with companies opting for low-cost production hubs such as China, Bangladesh, and Vietnam. However, cost alone is no longer the sole deciding factor—brands are now focusing on transparency, compliance, and production agility.

- Ethical Sourcing and Compliance: Consumers are increasingly demanding fair labor practices and environmentally friendly production. Certifications like WRAP, BSCI, and GOTS are becoming a necessity rather than an option. Brands failing to meet these standards risk reputation damage and legal issues.

- Nearshoring and Diversification: With geopolitical tensions and fluctuating tariffs affecting trade routes, brands are looking at nearshoring options in Mexico, Turkey, and Eastern Europe to reduce lead times and dependency on Asia.

- Supply Chain Resilience: The COVID-19 pandemic and shipping disruptions highlighted the vulnerabilities in global supply chains. Smart brands are adopting dual sourcing strategies, ensuring they have alternative suppliers in different regions to minimize risks.

Key Strategies for Apparel Brands to Optimize Overseas Sourcing

1. Enhancing Supplier Collaboration for Long-Term Success

At RYZEAL Sourcing, we emphasize the importance of strategic supplier relationships rather than transactional engagements. Many brands make the mistake of switching manufacturers frequently in search of lower costs, often at the expense of quality and reliability. Instead, brands should:

- Invest in long-term partnerships with trusted suppliers who align with their brand values and quality expectations.

- Engage in collaborative production planning to ensure suppliers have a clear understanding of design expectations and timelines.

- Foster transparent communication channels using digital sourcing platforms for real-time tracking and updates.

2. Leveraging Digital Sourcing & Smart Manufacturing

The future of apparel sourcing is digital. With AI-driven analytics, blockchain-based transparency, and virtual sampling technologies, brands can significantly reduce sourcing errors and production waste.

- AI-powered demand forecasting helps brands adjust production plans based on real-time market trends, preventing overproduction and deadstock.

- Blockchain solutions are enabling supply chain transparency, ensuring brands can track materials from farm to factory.

- 3D virtual prototyping tools such as CLO 3D and Browzwear are reducing the need for physical sampling, cutting costs and lead times.

3. Risk Mitigation: Balancing Cost and Quality

Overseas sourcing will always come with inherent risks, but brands must focus on risk mitigation rather than risk elimination. Here’s how:

- Diversify supplier bases across multiple regions to avoid single-source dependencies.

- Secure legal contracts with clear dispute resolution clauses to protect against supplier negligence or contract breaches.

- Pre-book production slots in high-demand factories to avoid seasonal bottlenecks and production delays.

- Implement robust quality control processes at different stages—raw material procurement, mid-production checks, and pre-shipment inspections.

Final Thoughts: The Future of Apparel Sourcing in a Competitive Landscape

As global sourcing landscapes evolve, brands that adapt, innovate, and embrace digital transformation will be the ones that thrive. Apparel brands must shift from price-driven decision-making to strategic, long-term sourcing partnerships that focus on quality, sustainability, and supply chain resilience.

At RYZEAL Sourcing, we continue to support brands in navigating the complexities of global sourcing by providing data-driven insights, supplier vetting expertise, and strategic sourcing solutions that optimize costs without compromising quality. The future of apparel sourcing is not just about finding the cheapest factory—it’s about building a supply chain that aligns with long-term brand goals, consumer expectations, and sustainable business practices.

References

- amfori BSCI. (n.d.). amfori BSCI Compliance Standards. Retrieved from https://www.amfori.org/content/amfori-bsci

- WRAP. (n.d.). Worldwide Responsible Accredited Production (WRAP) Standards. Retrieved from https://wrapcompliance.org/

- Fair Trade Certified. (n.d.). Fair Trade Apparel and Textile Standards. Retrieved from https://www.fairtradecertified.org/

- Global Organic Textile Standard (GOTS). (n.d.). GOTS Certification Standards. Retrieved from https://global-standard.org/

- OEKO-TEX. (n.d.). OEKO-TEX Certification and Standards. Retrieved from https://www.oeko-tex.com/en/

- ISO. (n.d.). ISO 9001 Quality Management System Standards. Retrieved from https://www.iso.org/standard/62085.html

- SEDEX. (n.d.). Supplier Ethical Data Exchange (SEDEX) Compliance. Retrieved from https://www.sedex.com/

- Intertek. (n.d.). Consumer Goods Testing and Quality Control. Retrieved from https://www.intertek.com/consumer/

- SGS. (n.d.). Softlines & Accessories Testing Services. Retrieved from https://www.sgs.com/en/consumer-goods-retail/softlines-and-accessories

- Higg Index. (n.d.). Sustainable Apparel Performance Measurement. Retrieved from https://apparelcoalition.org/the-higg-index/

- Just Style. (n.d.). How to Choose the Right Garment Manufacturer. Retrieved from https://www.just-style.com/analysis/how-to-choose-the-right-garment-manufacturer/

Additional Resources for Further Reading

- Better Cotton Initiative (BCI): https://bettercotton.org/

- Apparel Impact Institute: https://apparelimpact.org/

- Fashion Transparency Index: https://www.fashionrevolution.org/resources/transparency-index/